ASAPprime® Packaging

ASAPprime® Packaging Selection Without Screening

ASAPprime® enables determination of packaging without the need for package screening studies.

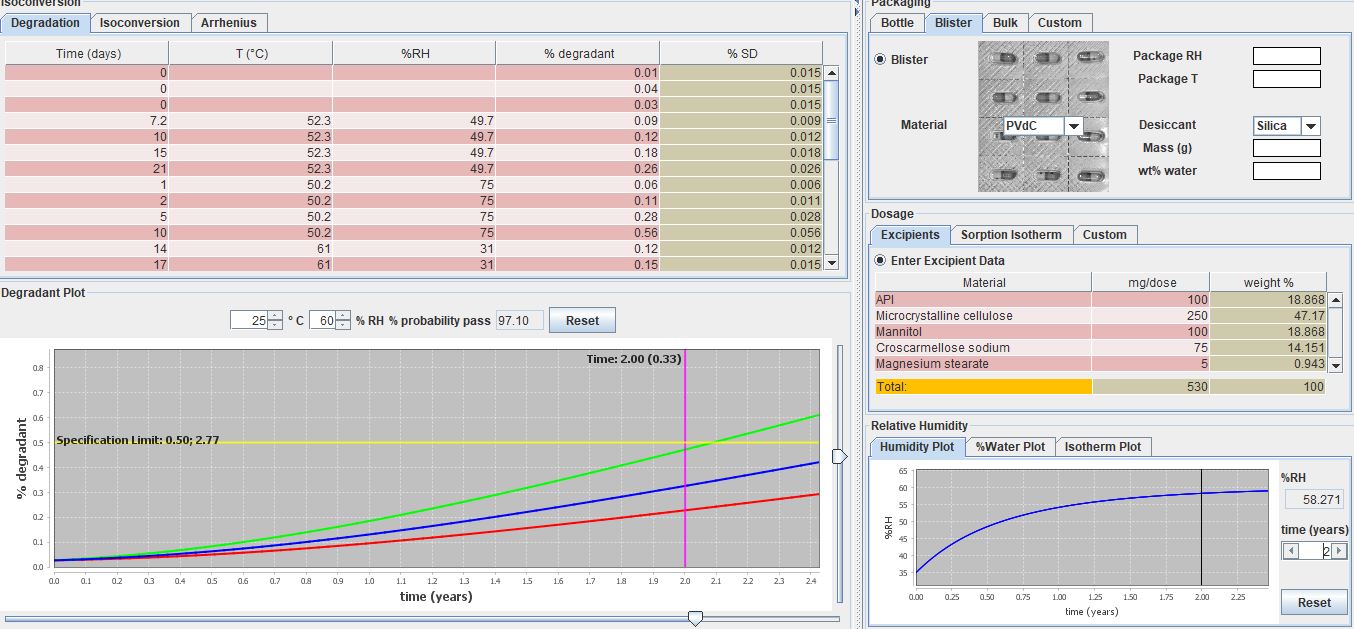

ASAPprime® calculates the RH as a function of time inside a package using the balance of moisture transfer rates (controlled by packaging permeability) and the ability of the product to hold moisture as a function of RH (controlled by the product’s moisture sorption isotherm).

ASAPprime® uses an extensive database of both packaging material moisture permeabilities (bottles, blisters and drums) and moisture sorption isotherms of most pharmaceutical materials that allow calculation of formulation isotherms. These determine a product, package and storage condition-specific moisture versus time behavior.

ASAPprime® combines the RH as a function of time with the calculated moisture sensitivity of the product to determine the impact of packaging on the product shelf-life. This is expressed as a percent probability of passing.

The software can include desiccants such as silica gel and molecular sieves. The calculations are accurate enough to determine the impact of tablet or capsule count on the shelf life of bottled products.

ASAPprime® allows the scientist to look at many “what if” scenarios. For example, the scientist can adjust the initial water content of the product, predict what would happen if there was a shipping excursion, or consider the impact of changing climate zones.

The ability to evaluate many packaging options using the software enables better optimization than is practical in real-time studies.

Companies have successfully used ASAPprime® as part of cost modeling, where they balance product volumes, global distribution versus zone-specific packaging and shelf-life in different zones. This ultimately allows companies to effectively model many potential scenarios without additional testing to make decisions about packaging quality and cost.

Example screen shot of a product packaged in PVdC thermoformed blister. The RH inside the package (for 25°C/60%RH storage) at 2 years is 58% which allows the product to have a 97% probability of being below the specification limit at that point. Packaging in PVC would not provide adequate stability for this product.