FreeThink Stability Laboratories

FreeThink Stability Testing Laboratories Include Highly Skilled Experts using the World’s Most Sophisticated Scientific Methods for Shelf-Life Stability Testing:

We use statistically based accelerated stability modeling to determine the shelf-life of most products and provide solutions to stability problems.

-

Our scientific teams include both analytical chemists, who can develop and execute ASAPprime® stability programs, and physical scientists who can mathematically model results.

-

Our global clients range from small biotechs to multibillion-dollar pharma companies

-

We handle almost all drugs and other types of products from multivitamin soft gels to complex combination intravenous solutions; from lyophiles to tablets.

-

Our team of world-class scientific experts develop stability-indicating analytical methods and provide mechanistic insights.

-

We carry out ASAPprime® studies, including fully compliant cGMP ASAPprime® studies, to determine product shelf-life accurately in just a few weeks.

-

We can often find solutions to stability problems based on our expertise in formulation and packaging options.

The details:

While many laboratories carry out method development and traditional stability studies, FreeThink scientists are especially adept at quickly solving the most challenging development problems. FreeThink scientists pride themselves on finding solutions where many others have failed.

Contact a Lab Services Expert

Stability Indicating Analytical Method Development

Shelf-life is based on increases in something undesirable (e.g., degradation products, color, smell) or decreases in something desirable (e.g., activity or potency, dissolution rate). FreeThink develops appropriate analytical methods for quantifying these changes for a wide variety of pharmaceutical and non-pharmaceutical products, including those with multiple actives, actives with no chromophores, and materials with difficult separations.

It is often critical to extract the active and degradants from the product matrix. FreeThink develops appropriate (up to fully validated) sample preparation methods by:

- Identifying solvents with the right solvation tendencies.

- Determining the form of energy to apply to help speed dissolution.

- Developing a filtration or centrifugation process to separate active and degradants from insoluble materials.

- Testing that the extraction method recovers active quantitatively.

Dissolution

For tablets and capsules, dissolution methods and stability are key considerations. We develop methods that can be “fit-for-purpose” through full validation:

- The solubility of the active as a function of pH establishes whether solubilization is necessary for “sink” conditions (e.g., the active is well-below saturation when the entire amount is released). Appropriate solubilizing agents (e.g., surfactants) are added.

- UV-visible analysis absorption spectroscopy is preferable; however, an HPLC potency assay may be needed. Most often at FreeThink, dissolution testing methods are developed using baskets (USP method I) or paddles (USP method II).

- FreeThink works with the sponsor company to establish specification limits (“Q-values”).

ASAPprime® Studies

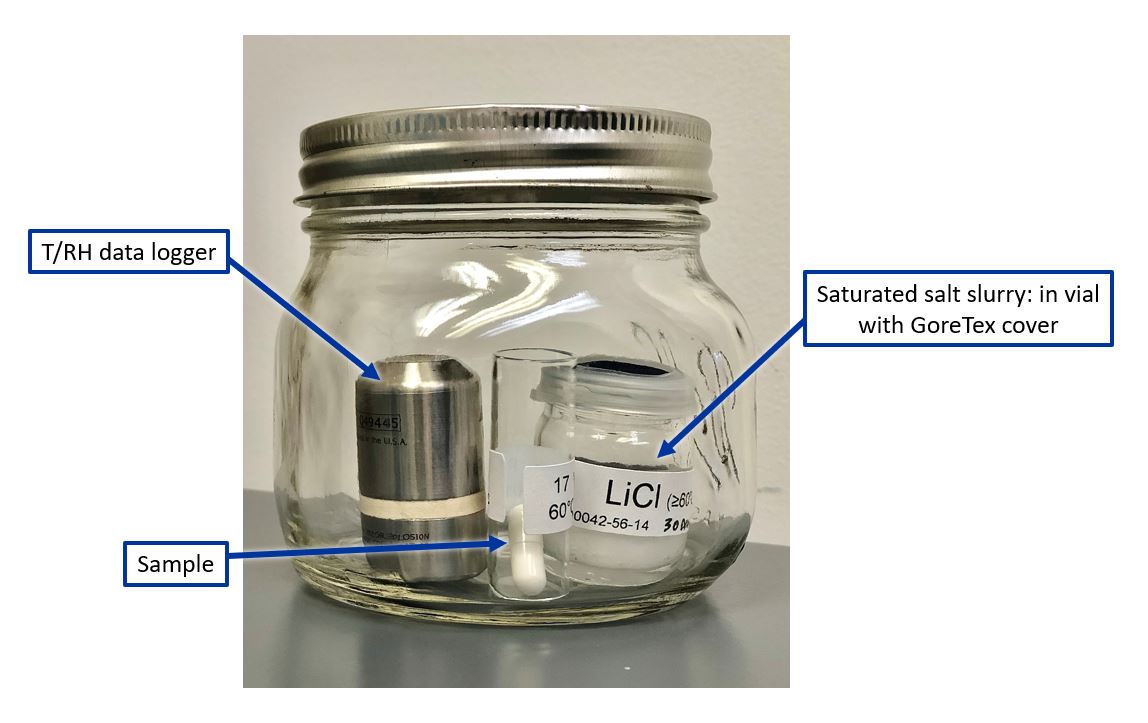

Example of a FreeThink pharmaceutical degradation testing setup.